University of California Irvine (UCI) scientists have achieved a significant breakthrough in the quest for more sustainable electric vehicle (EV) batteries. They developed a revolutionary chemistry that creates long-lasting, cobalt-free lithium-ion batteries, with nickel playing a key role.

Currently, cobalt is commonly used as a stabilizing agent in EV batteries, but it is expensive and primarily sourced from the Democratic Republic of Congo. To address this issue, Professor Huolin Xin, UCI’s professor of physics and astronomy, and his team explored the potential of nickel to replace cobalt. By using nickel in the battery’s cathode, they were able to reduce costs significantly, potentially saving between $20 to $25 per typical EV battery.

Beyond cost benefits, the adoption of nickel chemistry also brings enhanced safety and sustainability. Professor Xin’s chemically-doped material ensures better thermal cooling, reducing the risk of battery fires compared to batteries with traditional materials.

The breakthrough was achieved through a process called concentrated doping, where the chemistry of an element can be altered, much like modifying ingredients in a recipe. According to Professor Xin, it’s akin to changing chocolate chips in a cookie recipe, with the battery’s core remaining intact.

Consumers stand to gain significant benefits from this innovation. Batteries incorporating Professor Xin’s nickel chemistry offer improved charging and driving performance. With just a 5-minute charge, an EV equipped with his chem material can cover an impressive 150 miles, a marked advancement compared to current EV batteries.

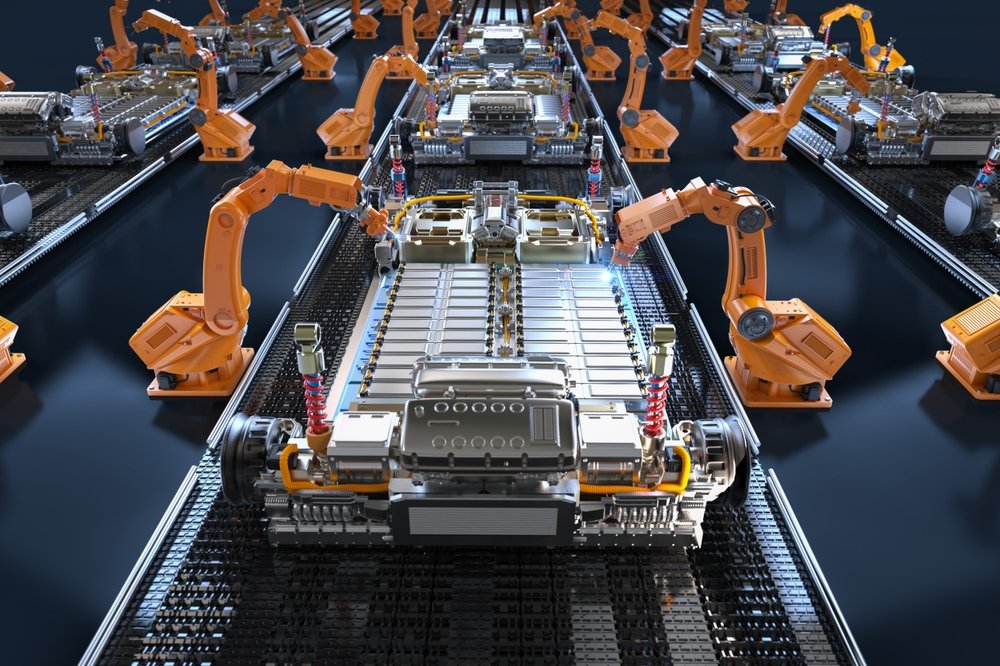

The potential of nickel chemistry to transform the EV industry has caught the attention of various automakers. Professor Xin is already in discussions with EV manufacturers to upscale the design and integrate these batteries into the next generation of electric vehicles. This development promises to make EVs more sustainable, cost-effective, and safer, paving the way for a greener future of transportation.

May also be interesting: “Mining for innovation: the R&D structures of steel companies at work.”